Ao Xinghua and his brother Ao Xingqiang pour molten copper into a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 17, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

This file photo taken in 2015 shows a part of a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

Ao Xinghua inlays turquoise into the handguard of a sword at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 16, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua wipes a finished lead-tin engraving artwork at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

This photo taken on June 17, 2025 shows a copper melting furnace working at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua engraves on a piece of lead-tin alloy to make a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua engraves on a piece of lead-tin alloy to make a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua grinds a piece of patterned lead-tin alloy at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

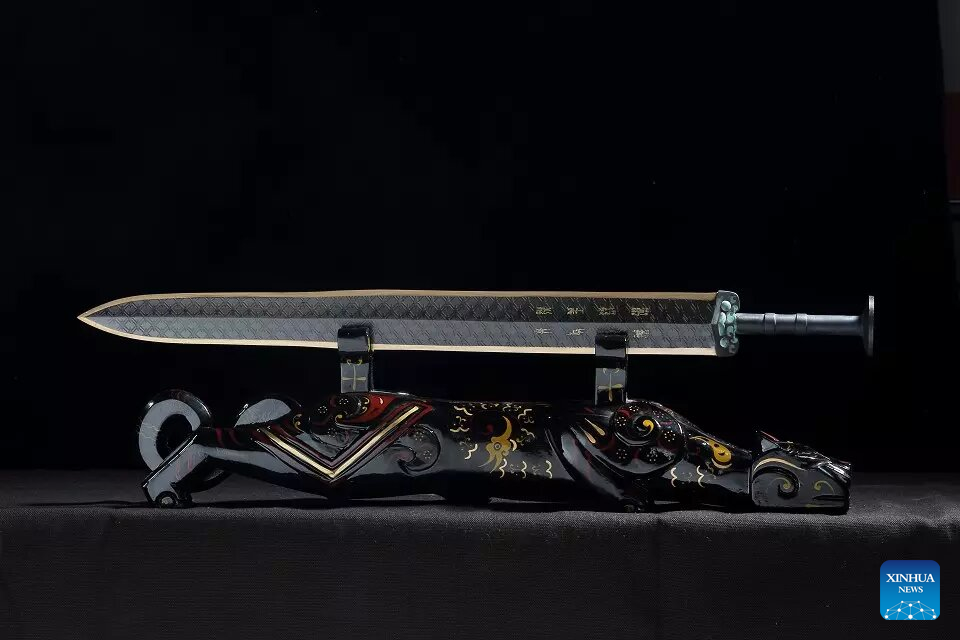

This file photo taken in 2015 shows a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

Ao Xinghua makes a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 16, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua makes a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 16, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua (R) and his brother Ao Xingqiang prepare to pour molten copper into a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 17, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua grinds an inlaid part at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 16, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

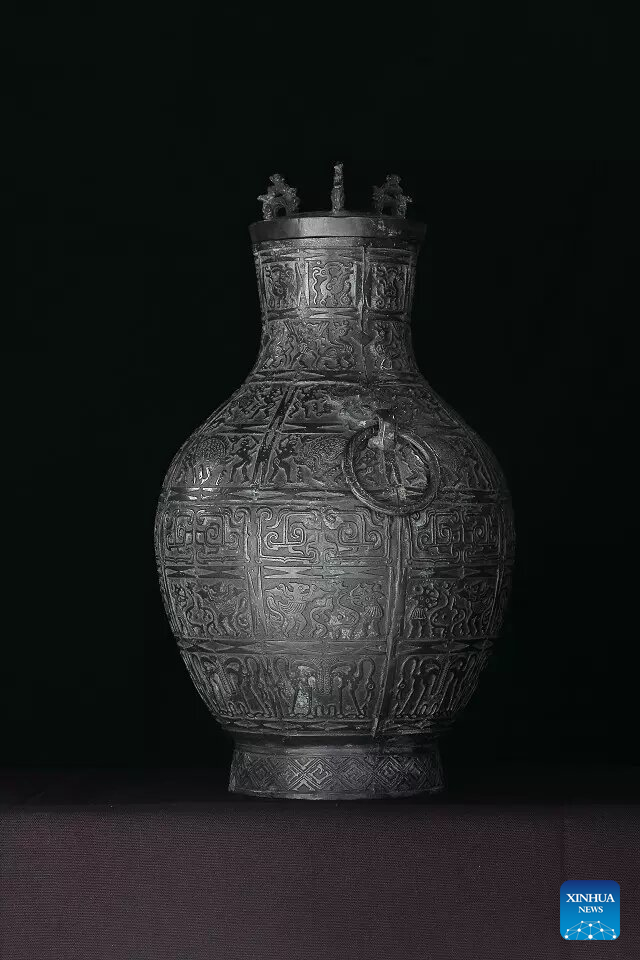

This file photo taken in 2015 shows a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

Ao Xinghua cleans a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 16, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua inlays turquoise into the handguard of a sword at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

This file photo taken in 2015 shows the silver-inlaid cloud-pattern box made by Ao Xinghua and his family.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

This file photo taken in 2015 shows a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

This file photo taken on Dec. 4, 2008 shows Ao Xinghua (1st L) listening to the introduction of his father Ao Chaozong (C) at Sujia Village in Jingzhou City, central China's Hubei Province.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

Ao Xinghua cleans a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

Ao Xinghua engraves on a piece of lead-tin alloy to make a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 24, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

This file photo taken in 2015 shows a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

Ao Xinghua (R) and his brother Ao Xingqiang pour molten copper into a mould at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 17, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua/Du Zixuan)

This file photo taken in 2015 shows a part of a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

This file photo taken in 2015 shows a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

This file photo taken in 2015 shows a part of a lead-tin engraving artwork made by Ao Xinghua.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."

Except for selling bronze ware artworks according to orders, their workshop today also cooperates with museums to repair and replicate cultural relics. Moreover, they also take part in important exhibitions and open classes on campus. "Making bronze wares is never an easy work, " said Ao Xinghua, "In hot summer, we have to stand for 10 hours beside the copper melting furnace which has a temperature of 1,200 to 1,600 degrees Celsius. " Due to its complicated making procedures, long production cycle, few learners and niche market, the craft of Lead-Tin Engraving is now facing great difficulty to develop and pass down. "Maybe one day we can only see bronze wares in showcases of museums, " said Ao Xinghua, "and the future of the art depends on whether the younger generations see its values." (Xinhua)

Ao Xinghua engraves on a piece of lead-tin alloy at Ao's family workshop in Buhe Town of Jingzhou City, central China's Hubei Province, June 16, 2025.

Lead-Tin Engraving, a mould-making craft used to create and replicate bronze ware, is known for its excellent work in reproducing the fine and exquisite patterns on ancient bronze ware. Mixing tin into lead to get a softer texture for making a mould, the craft can create both 2D and 3D patterns. The making of a bronze ware roughly goes through procedures like pattern designing, mud mould making, lead-tin mould making, engraving, molten copper pouring and grinding. In 2001, the craft of Lead-Tin Engraving was listed as one of the national-level intangible cultural heritages.

Lead-Tin Engraving craft has been passed down for five generations in Ao's Family in Jingzhou of central China's Hubei Province. Ao Xinghua, 52 years old, a fourth-generation inheritor, has been doing the work for over 30 years. Since childhood, he had followed his father Ao Chaozong, a national-level inheritor of the art who had mastered all the procedures of making a bronze ware, to get in touch with the craft. "My grandfather and father regarded the art as their lives, and had devoted all they have into it," said Ao Xinghua.

Nowadays, Ao Xinghua and his brother Ao Xingqiang work together at their family workshop, with the former focusing on production and the latter on marketing. Making a bronze ware usually costs several months or even years, and Ao's family has concluded a series of mental and oral pith instructions to guide their work. "All the skills must be grasped through long-time repeated works, and that costs time, " said Ao Xinghua.

In 2010, led by Ao Chaozong, Ao's family created a silver-inlaid cloud-pattern box which took part in the Shanghai World Expo. "The box cost us seven people half a year to make, " said Ao Xinghua, "we applied all our crafts onto this one piece of artwork, which can represent a high-standard of Lead-Tin Engraving. " In his 30 plus years, Ao Xinghua never stops upgrading his skills and deems himself "have not totally mastered the art" and "still need to learn."